FlexIn Heat®

Our technology that changes everything

Want a bit of flexibility?

When it comes to induction heating, everyone immediately thinks of the best-known application: the kitchen. Not surprising, considering that by now almost everyone has come into contact with induction cooktops or pots at some point. The second thought that immediately pops into your head is “cool” or “the cooking surface isn’t even warm”. We rather think of “what else can be done with inductive heating? And we tell you here in confidence…a whole lot.

Those who know us a little bit, know that we never rest until we find the perfect technological solution. We always aim for more. So why not try to invent induction systems whose flexibility in terms of formability is as versatile as they are in terms of applications? Said and done. After many hours of brainstorming, development and countless tests, we managed to revolutionize induction technology with the help of DLR and were finally able to give the child a name. May we introduce our newest family member – FlexIn Heat®!

FlexIn Heat® is more than just inductive heating…

…and not only looks cool, but is efficient and effective in all respects without exception. If you know something about induction and the concept of the resulting heat, you can read on now. For everyone else, here is another explanation of the principle in all its simplicity.

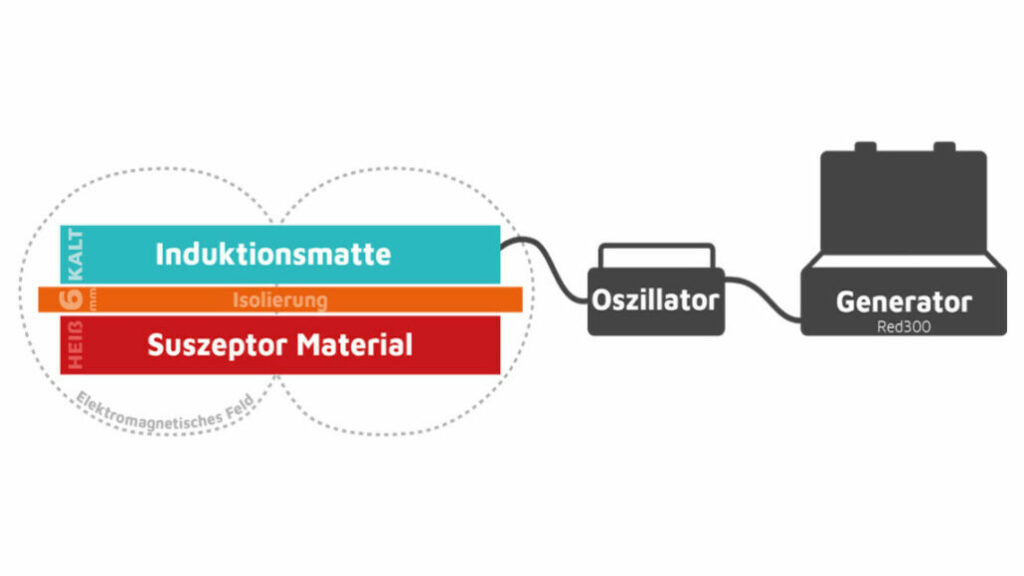

The core of our technology is, of course, the concept of electromagnetic induction, which describes the creation of heat through the use of electricity by means of electromagnetic fields. However, the heat is not generated just like that, but is the result of the resistance of the specific material used, which is put under voltage in the form of a coil. If the coil is energized, it is not the current itself that generates the heat, but the resistance of the material in conjunction with the eddy currents that occur. The whole process is then called the Joule heating effect, and it’s quite something. We make use of this effect, but in a different way than we thought.

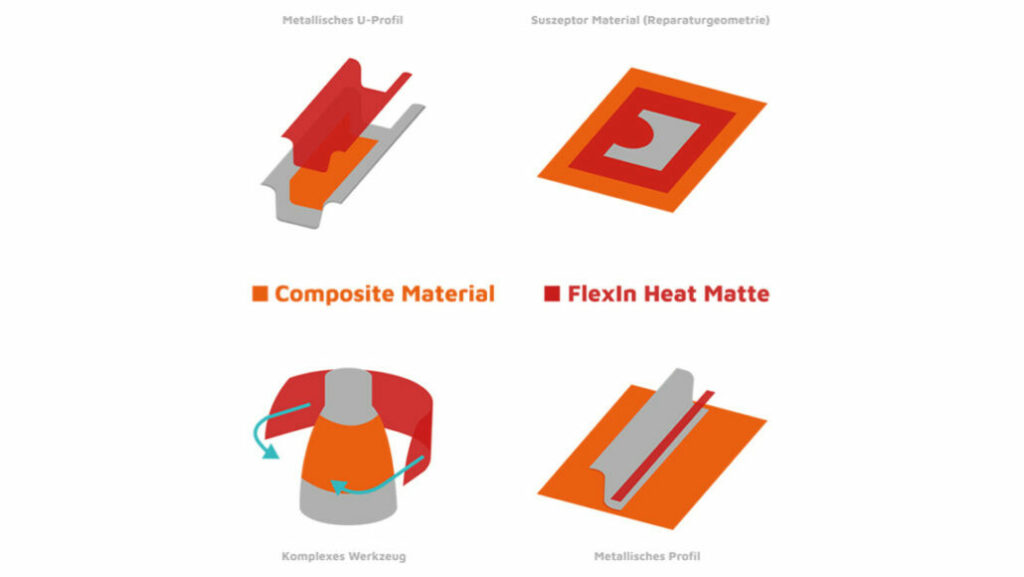

FlexIn Heat® technology is used in conjunction with our Hot Bonder Red300 and a heating blanket that contains a structure of flexible induction coils. These coils are the crux of the matter, and we love them so much that we patented the whole thing. It allows conductive materials/susceptors of any conceivable shape and geometry to be heated directly, flexibly, precisely, homogeneously, up to 400°C in a matter of minutes, regardless of the application, contact-free, and as easy as pie.

The induction coils are embedded in silicone or textile blankets and provide an incomparable flexibility with a maximum resistance. By the way, square or round geometries bore us. That’s why you can have your desired design created and produced on request. Isn’t is cool? We think so too. The optional insulation layer between our induction blanket and the susceptor with up to 6mm thickness, supports the heating process, ensures a perfect heat transfer, protects the heating blanket from too high temperatures and minimizes heat loss in the heating process.

More flexibility is not possible!

Anyone who can put 1 and 1 together knows how versatile the technology of electromagnetic heating can be and what benefits it provides. But we go one step further and enable you with our technology the following benefits:

progressive operation

high heating rates

modular design

scalable sizes

individual shapes and sizes

flexible & individual design

enormous power spectrum

contactless operation

It can’t be more flexible!

In addition, there are several possible areas of application in which our technology can be useful. For the “mindblow effect”, read on and let your creativity take its course.

Aerospace

Repair of damages of daily operation like shunting damages, water and frost damages etc. by means of mobile heating technology. By the way, individual adjustment of the heating ramp, data log and automatic report generation are included.

Automotive industries

Need new heating elements for curved surfaces or shapes inside the vehicle? We will gladly take care of it and support you, for example, with the technology for heated armrests, seats, steering wheels or fittings.

Composite Manufacturing & Repair

Everyone can use a surface heating system integrated into the mold for time- and energy-saving production and repair of composite components. We even offer you the whole hoo-ha individually tailored to your needs and modular. Say hello to repair 2.0.

Industrial Tool Heating

Faster heating and significantly reduced energy consumption for maximum productivity? With our heating elements embedded in your press tool, this no longer sounds like visionary dreams. We shape the future with you!

Food Industries

Fast heating of the container surface, precise control of the temperature profile, more efficient and economical than alternative heating methods? We do, we can! Because non-contact, large-area heating of cylindrical molds can also be used in the food industry. Incidentally, we’re talking about roasting drums, homogenizers and the like, and thus making our contribution to the food industry. So let’s be honest, who doesn’t like coffee, roasted almonds, cocoa or brittle?