That’s great – I think to myself!

But we don’t want to take off at msquare. For us, hot air is an important medium for composite repair and the production of composite components. Heating technology is important here to ensure that epoxy resins can cure properly. If heating is used in composite repair, curing times can be reduced significantly. There are many possibilities for heating composites, but we are especially pleased that we can now also offer hot air as a heating technology for composite repair!

Composite heating with the RedAir fan heater

The hot air is produced by our fan heater “RedAir”. It is a temperature-controlled fan heater. It achieves temperatures of 200°C and thus it covers a large part of the common composite materials.

Since our RedAir fan heater not only heats but also blows properly, it achieves very good heat circulation on the component. This is a great advantage, especially for more complex structures with many angles and edges. The turbulent hot air prevents the formation of heat shadows or even local overheating.

Possible applications of the hot air system

We distinguish two different ways of using the RedAir fan heater:

- Fan heater in combination with a “tempering tent”.

- Fan heater integrated in a mobile hot air box

Both possibilities of use have the advantage that they are mobile heating solutions. This means that the composite component can be heated directly on site. The space to be heated is adapted to the component. This means that only the area that requires heat is heated, and no more volume is heated than is absolutely necessary. With its hot air, the RedAir fan heater offers a particularly efficient way of heating while still saving costs.

First fan heater with recirculation

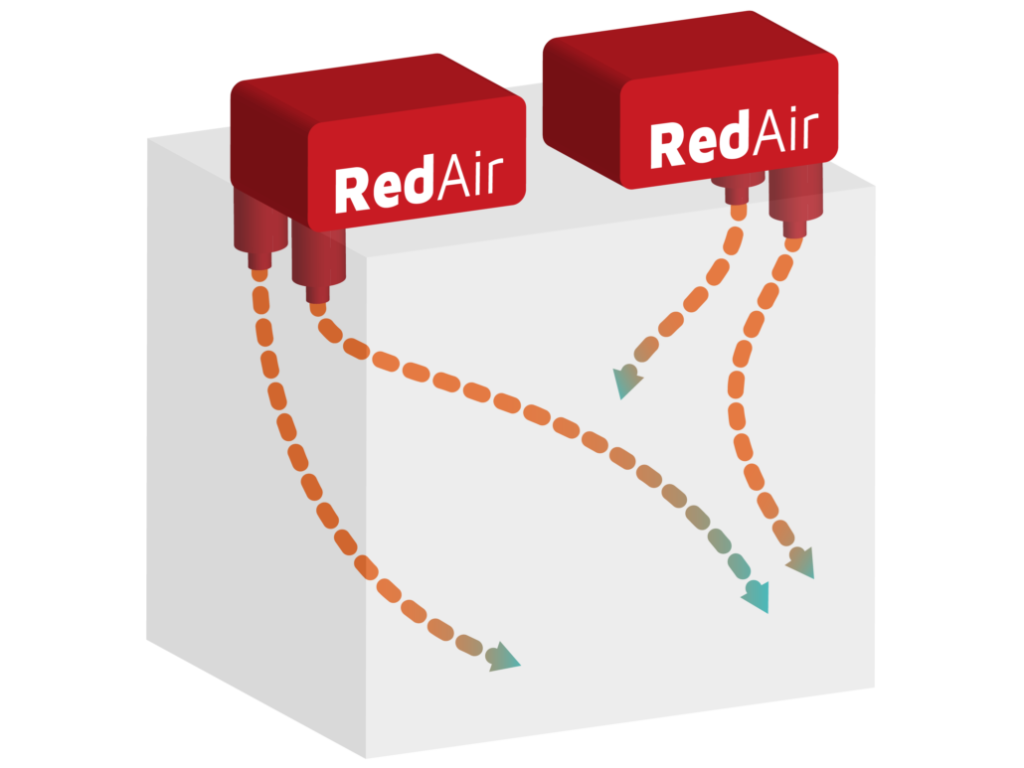

A very special highlight of our fan heater is that it can also heat in recirculation mode. This means that the hot air, after it has been able to act on the composite component, is returned to the fan heater. There it is heated again and directly reused. The great advantage is that this recirculation operation is much more efficient and sustainable than heating the ambient air permanently. In addition, due to the continuous blowing in and extraction, a better heat flow is achieved at the component than in simple heating mode.

My conclusion about the RedAir fan heater

So you see – hot air is much better than its reputation 😉 You can use it to heat your composite component, whether it’s for repairing an aircraft, rotor blade or boat – or for manufacturing large-area composite structures. With the RedAir heater, you can not only shorten the curing time and save time, but you also heat in a particularly energy-efficient way. And with the money you save there, maybe you really can take a trip in a hot air balloon.