Heating controllers operated via smartphone, tablet or PC

With the smart heating controllers and hot bonders from msquare, the digital transformation is taking place in the area of composite tempering and repair. Where analog rotary controls were previously used to set the temperature of the heating blanket, the msquare app “easyHeat” now facilitates the specific curing process when repairing fiber reinforced structures and offers significantly more options for precisely regulating the heating process, e.g. by entering a heating ramp and other functions.

Via an internal WLAN connection with a range of up to 120 m, the operating parameters for the tempering process are conveniently set remotely via smartphone, tablet or PC and monitored via live tracking. The long range of remote operation is particularly advantageous for the rotor blade repair of wind turbines.

Live monitoring of the heating process and data logging

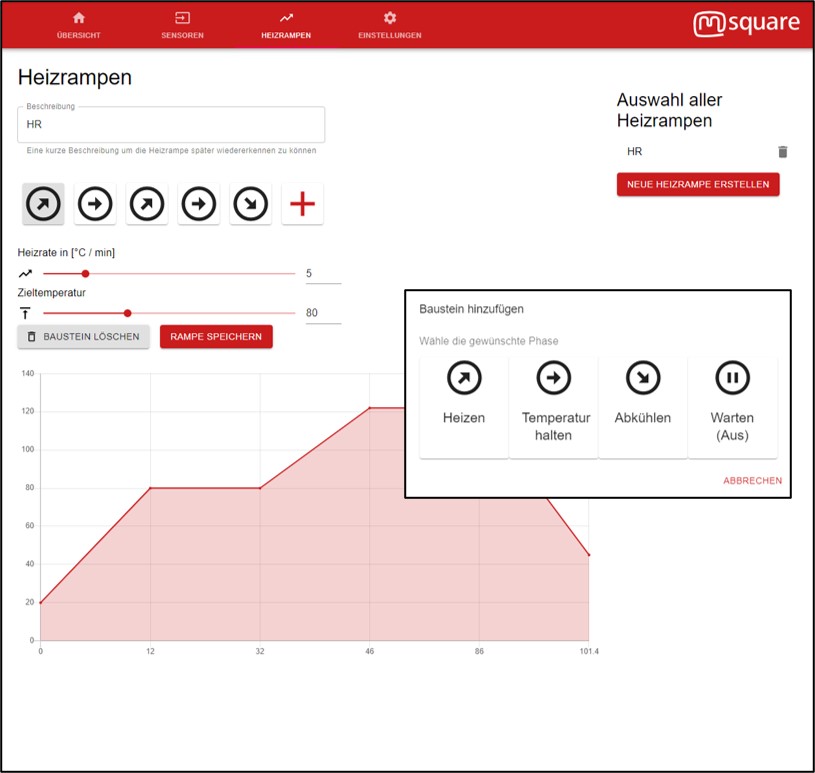

In addition to the target temperature, the heating rate in °C/min and the dwell time can be entered in the RedZero and Red300 digital heating controllers via the easyHeat software to allow for a controlled heating of the heating blanket. By precisely defining this heating ramp, the specific conditions of the individual repair site are optimally taken into account, which always requires a different, individual heating process depending on the material and resin used.

Last but not least, this ensures compliance to the manufacturer’s repair specifications. And as a matter of fact this can be easily documented because digital heating of composites also offers the advantage that the entire data of the heating process (temperature, time and maximum deviation) is continuously logged and, if necessary, transferred to an automated repair protocol.

In this way, it is possible to trace which temperatures have affected the composite component during the heat cycle – a documentation that takes precautions and significantly reduces the effort required for manually created reports.

Defining heating ramps and controlling temperature

Once defined, the heating ramp can be stored in the system and recalled or repeatedly performed at any time. In addition, the Hot Bonder Red300 offers the possibility of connecting multiple temperature sensors in parallel. The easyHeat software can then be used to define which thermocouple shall be used to control the heating process; an average across all sensors can also be used as the basis for control.

Nevertheless, the temperature of all sensors is always evaluated and graphically displayed. If a software update is pending, it can of course be downloaded “over the air” to the heating controller or the Hot Bonder. In case of special requirements an adaptation of the software to the needs of the respective application is possible.

Contact us or simply test our heating controllers and the easyHeat software yourself.